- Summary

-

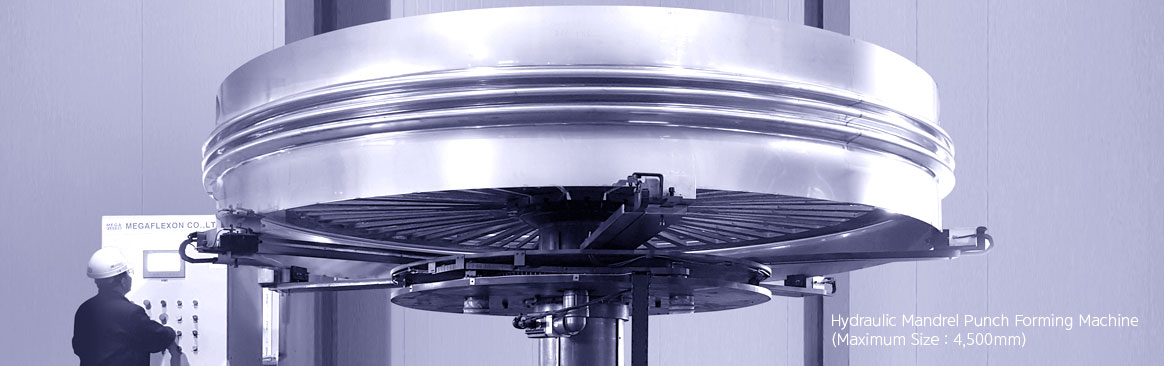

The selection of the optimum expansion joint depends on a technical as well as an economical aspect. With many years of experience in design, production and marketing of expansion joints, we are competitive and specialized on the know-how on the solution for demand required in a technical and economical view.

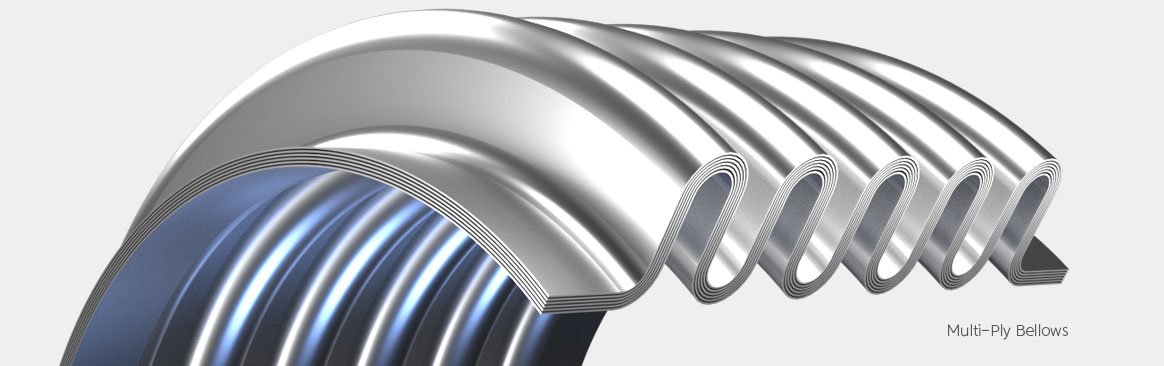

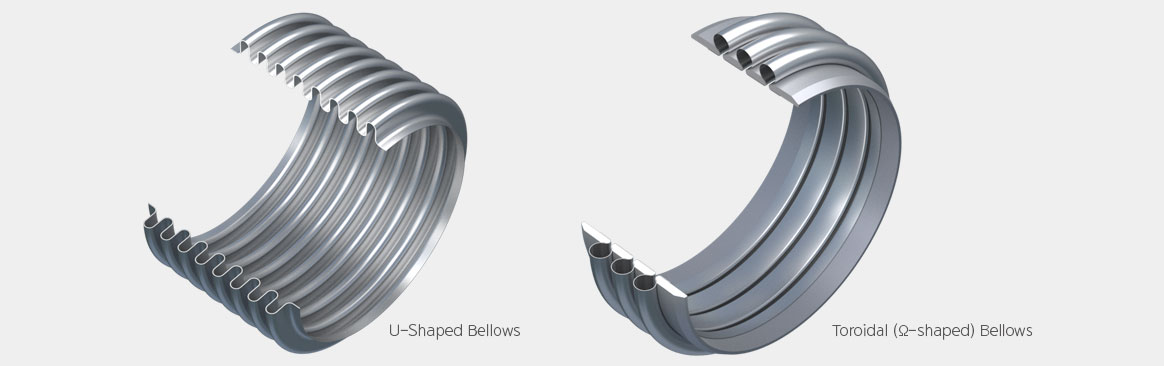

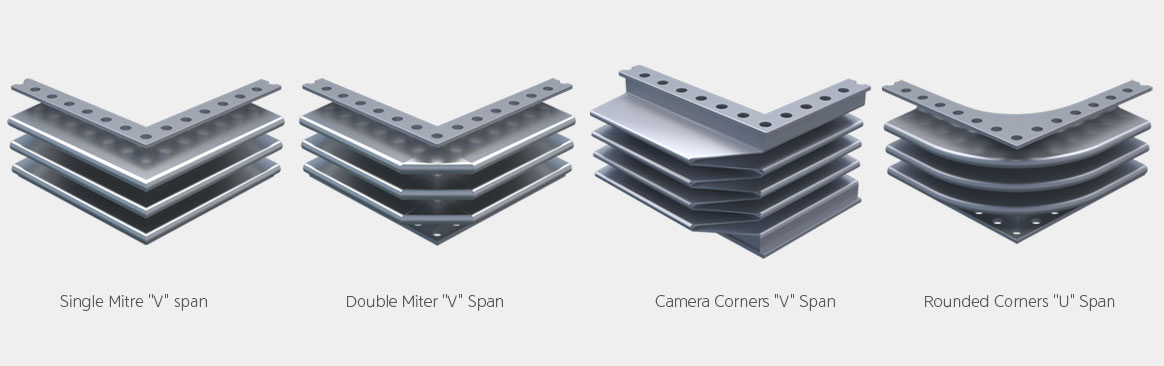

The physical capacity of bellows to absorb movement is determined by the number of corrugations, pitch (P), height (H), pipe diameter (D), spacing (L), thickness of material (t), and number of layers (n). The basic constituent element of expansion joint, bellows can be specified, considering on movement, pressure, temperature, service life and corrosion rate required.

- MENU

- About

- Product

-

METAL EXPANSION JOINT

- MENU

- METAL EXPANSION JOINT

- BASIC DESIGN

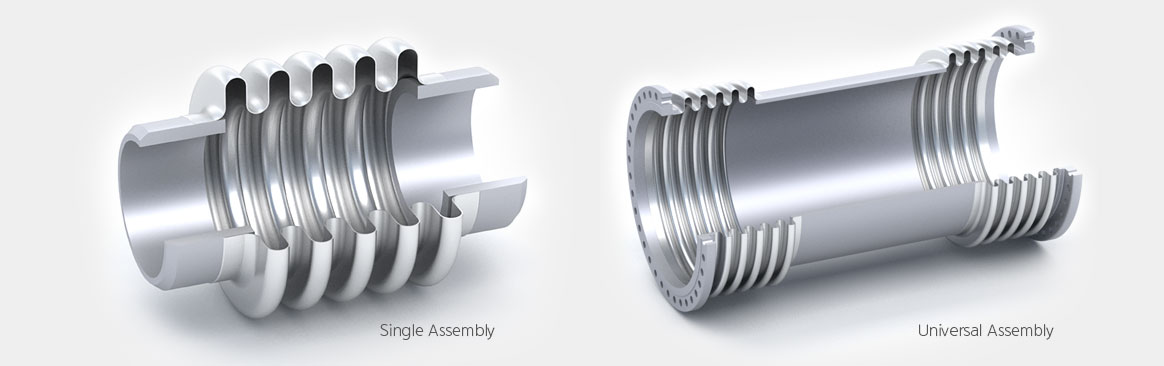

- Single Type

- Universal Type

- Hinged Type

- Gimbal Type

- Rectangular Type

- SPECIAL DESIGN

- Pressure Balanced Type

- Thick Wall/Flanged & Flued Type

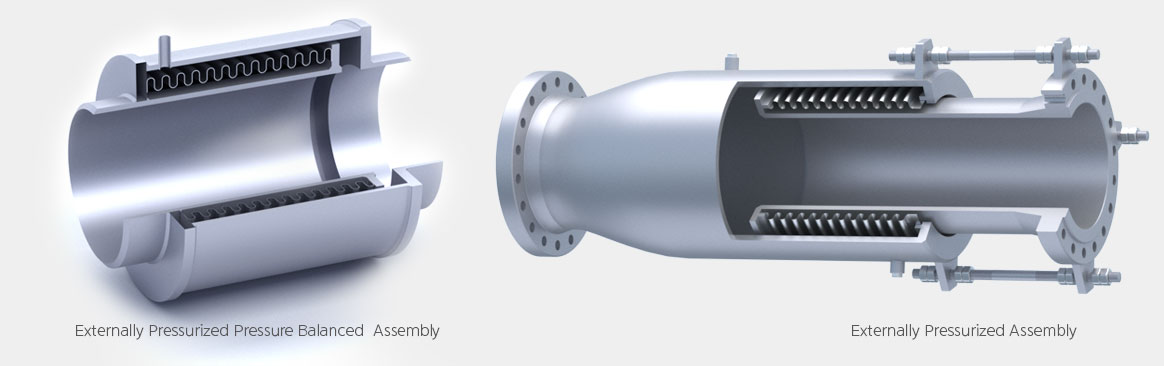

- Externally Pressurized Type

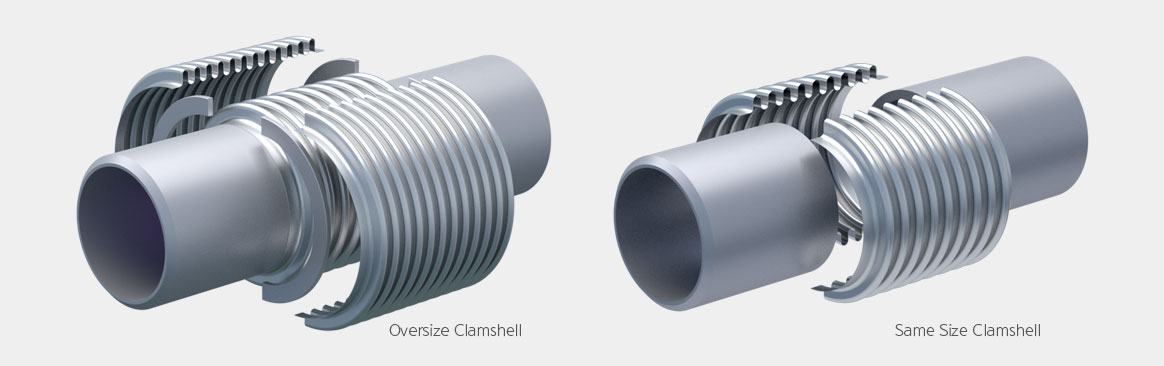

- Jacketed Type- Clamshell Type

- Clamshell Type

- Two-Ply Testable

- PTFE-lined Type

- High Pressure Type

- FCCU Expansion Joint

- Pantograph Type

- MENU

- RUBBER EXPANSION JOINT

- FABRIC EXPANSION JOINT

- FLEXIBLE METAL HOSE

- Quality

- Services

- News

- Gallery

- Catalogs